Why Polymate Trailers are Australia's No.1 Choice

Why should I buy a Polymate Trailer?

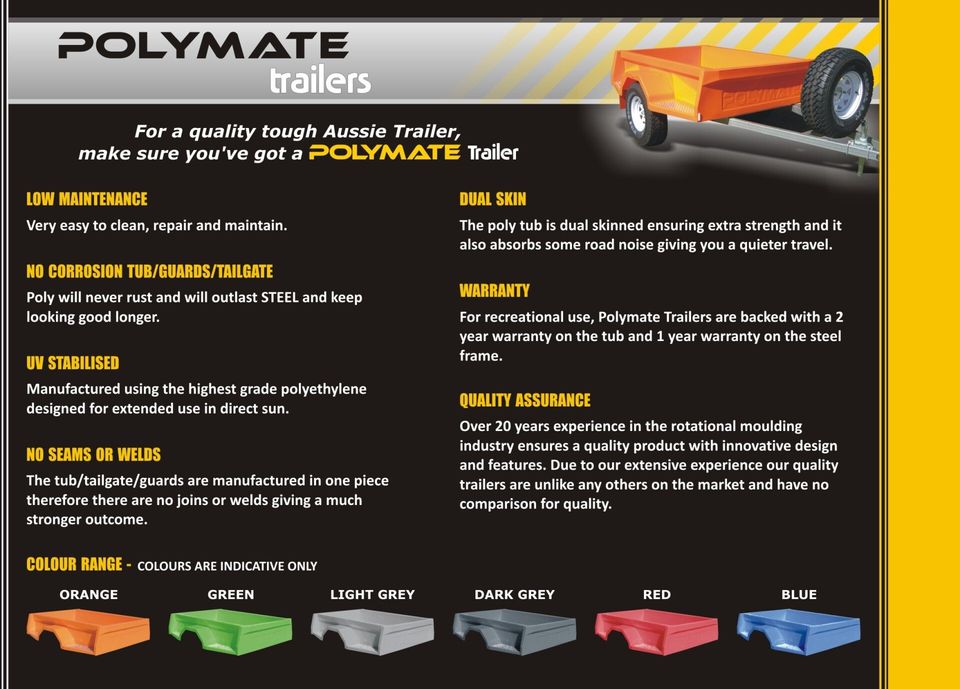

Corrosion free components: Our components will never rust, which keeps your trailer in tiptop condition for its entire lifetime.

Strength and durability: The Polymate Trailer is moulded as one piece. With no joins or welds, the trailer is incredibly strong and can withstand heavy loads.

Low maintenance:

Our trailers are easy to clean and maintain, and will never

require painting.

Performance: Polymate Trailers absorb surface noise, silencing rough roads and ensuring a smooth ride.

Polymate Trailers Manufacturing

Polymate Tubs are all made and produced in one location - NO OUT SOURCING (Design, Moulding, Production, Frame Fabrications, Assembly, Fitting - all at Polymate Factory)

No out sourcing overseas products

2 generations, 30 years experience in Rotational Moulding and Fabrication Industry

The original and only lasting Poly Trailer on the market that can be guaranteed and proven for strength, integrity and overall performance